3D scan

With our measuring technology, we can precisely measure almost any material using 3D scanning. We use tactile and/or high-resolution optical measuring techniques. The high information density generated by 3D scanning is incomparable with conventional measuring technology. Our mobile 3D scanning process allows the measuring device to be brought to the object being measured. Measurement orders can therefore be placed directly at your location, or you can send us your component and we will perform the 3D scan in-house.

The RevDop team is happy to help you!

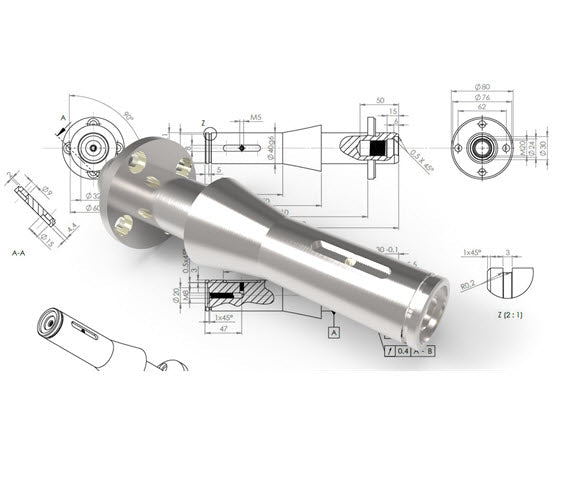

Reverse engineering

– precise digital reconstruction for prototypes, RIM molds and PU components

With our reverse engineering service, we digitize existing components or molds with the highest accuracy and make them usable for modern manufacturing.

Using high-resolution 3D scanning technology, we create highly detailed point clouds that are converted into precise CAD models. This allows complex geometries, tools, or plastic parts to be reproduced, optimized, and adapted for the RIM process or PU potting.

Our specialists combine precise measurement technology with sound design know-how to efficiently digitize components – whether for quality assurance, reproduction of outdated tools or for design changes in small series production.

Advantages of our reverse engineering:

- High accuracy in component reconstruction

- Direct CAD modeling based on 3D scan data

- Optimization and adaptation for RIM molds, PU potting and injection molding

- Ideal for spare parts manufacturing, redesign or mold reproduction

- Fast project turnaround times thanks to digital workflow

Whether prototype, small series or series tooling – we deliver a digital image of your component, ready for further processing in design and manufacturing.

construction

Are you planning to optimize or customize a new or existing product? RevDop's 3D Scanning and Design department creates a project plan for your requirements and implements them professionally and quickly, based on an existing or yet-to-be-created CAD model! From data acquisition via 3D scanning to reverse engineering, design engineering, prototype construction, and mold construction for the economical implementation of small series, the RevDop team accompanies you as a reliable partner in your project, right up to the final

Implementation.

Small series production

– flexible, economical and precise thanks to innovative mold making

Our small-batch production enables the fast and economical manufacture of high-quality plastic components – perfect for prototypes, pre-series production and small quantities.

By using modern manufacturing technologies and our innovative mold making, you can save up to 90% on tooling costs compared to conventional methods.

innovative mold making

We combine additive manufacturing (3D printing) and PU mold making with traditional toolmaking. This allows us to produce molds in the shortest possible time and respond flexibly to design changes. For projects requiring the highest precision or special material and surface finishes, we also have a partner company whose large-capacity 3D milling machine enables us to offer our customers conventional mold making services as well.

With this combination of innovative and traditional manufacturing technology, we offer you maximum flexibility, short lead times and an ideal balance between cost, quality and speed.

Your benefits

- in our small series production:

- Up to 90% lower tooling costs through additive mold making (3D printing, PU molds)

- Economical production of small quantities (10–5,000 parts)

-

RIM process (Reaction Injection Molding) for complex and robust PU components

- Flexible combination of 3D-printed, PU and milled shapes

- Fast delivery times thanks to in-house design and manufacturing

- Ideal for functional prototypes, spare parts, zero series and series validation

RevDop – Your partner for economical small-batch production using the RIM process and PU potting.

Innovative mold making meets precision – for efficient, high-quality plastic components in record time.